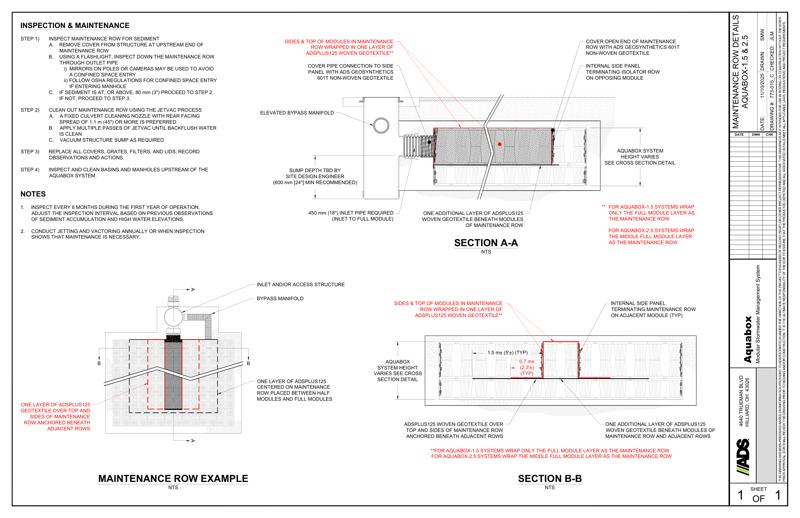

Maintenance Row Details Aquabox 1.5 - 2.5

Filename:

Maintenance Row Details Aquabox 1.5 - 2.5.pdf

This document is the Isolator Row Details Aquabox – 1.5. Cross sections of the Isolator Row, inspection and maintenance with notes provided.

The Section A-A cross section shows the cover pipe connection to side panel with ADS Geosynthetics non-woven geotextile, sump depth, sides/top of modules wrapped in 1 layer of woven geotextile, elevated bypass manifold, inlet pipe, cover open end and internal side panel terminating isolator row on adjacent module.

The Section B-B cross section shows the sides/top of modules wrapped in 1 layer of woven geotextile, woven textile over top/sides of isolator row anchored beneath adjacent rows, 1 additional layer of woven geotextile beneath modules and internal side panel terminating isolator row on adjacent module.

The Isolator Row example shows the bypass manifold, inlet/access structure, sides/top of modules wrapped in 1 layer of woven geotextile, woven textile over top/sides of isolator row anchored beneath adjacent rows, 1 additional layer of woven geotextile placed between cube modules and full modules.

Step 1 under inspection and maintenance require inspection of Isolator Row Plus for sediment has 3 steps to execute inspection. Step 2 notes to clean out isolator row using the jetvac process, step 3 is to replace all covers/grates/filters and lids, step 4 is to inspect and clean basins/manholes upstream from the aquabox.

A note suggests inspection occur every 6 months during the first year of operation and to adjust schedule based on observations of sediment. A maintenance note asks to conduct jetting and vactoring annually or when maintenance is necessary.